CLASS WORK PROJECT

DESIGN OF POLICE SIREN USING NE555

Introduction

A siren is a loud noise making device.

Sirens are mounted in fixed locations and used to warn of natural disasters or attacks.

Sirens are used on emergency service vehicles such as ambulances, police cars and fire tracks

Background

This police siren simulated electronic project uses two 555timers IC to generate a sound similar to a police siren.

A single 556 timer IC which consists of two 555 timers can also be used. In this circuit both of the timers are configured as a stable circuit.

Problem Statement

Due to the need to alert people in case of emergencies such as police vehicles and ambulances.

Significance of the project

The whole idea of the siren was to alert the public about emergency cases. The Siren finds application in police vehicles, ambulances.

General Objective

The general objective of this project was to understand the operation of a siren. By making a run up of the project, theoretical knowledge was transferred into practice and during the hardware implementation, practical skills such as a printed board implementation, circuit testing and soldering were enhanced.

Specific Objective

To design a simple Police siren.

Scope of the study

The project only focuses on producing loud sound which brings about sound pollution to the environment. Some instruments such as bazar where hard to find and generally expensive.

It took us a lot of time to make a working siren without mistake.

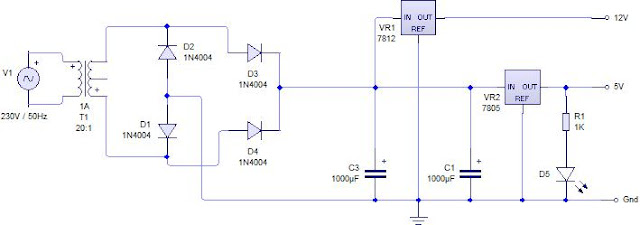

Circuit diagram:

Materials and Quantity

Capacitors

100µF 1

100nF 1

1µF 1

10µF 1

Resistors

68KΩ 2

8.2KΩ 2

1KΩ 1

Diode

1BH62 1

IC NE555 2

Buzzer

64 ohm, 500mW 1

Battery

10v 1

LED

Red &blue 2

Variable resistor 1

Print board 1

Jumpers

Switch 1

TUMUSIIME BENON

SEKITTI HAMIS

ARYAMANYA EDWIN

SEGUYA ENOCK

SISYE GARVIN

KASAMBA GEORGE

ANGURIA MAX

MUTABAZI ARBAN

KIBALAMA JOEL

SITAKU OSCAR

UMA STEPHEN

ARIHO LEWIS